Don’t waste your hard-earned money following false CNC ‘experts’

Now you can do it easily using basic tools and low-cost components

Make sure your sound is turned on – Click to Play/Pause video

I’m going to show you these simple secrets…

- How to make your CNC router super rigid so it easily cuts aluminum without vibrating, flexing or chattering like crazy

- How to choose the right materials, parts and components without wasting tons of money

- How to avoid the need for expensive, hard to use machine tools like milling machines and lathes

Read on an I’ll give you my simple-to-follow strategies that avoid the worst and most expensive mistakes DIY CNC builders make.

Turn that CNC router you’ve always wanted into a reality.

- You might be thinking that all this information is also available free on YouTube and forums like The CNC Zone.

- But you’d be mistaken, because what I’m going to show you is nothing at all like that.

- I’m going to tell you exactly what to avoid when building your CNC

- And I’ll be giving you all right steps to follow to assure your CNC router build is a success.

I’ll be telling you about…

- how to choose the best CNC router configurations and their strengths and weaknesses

- which components are right for your build and which are overkill?

- how you can start building your own super-rigid CNC router without wasting months and months researching, designing and test building your machine over and over.

I wasn’t always an expert in CNC Router Design, I was pushed into it by circumstances

Dave Field – KAL CNC Strategies

Professional Product Designer

Let me tell you about my own CRAZY CNC journey and how I came to design CNC machines…

It all started a few years ago when I’d approached by my friend Howard about investing in a product..

He liked my idea and had agreed to finance our venture.

Howard had asked me to cut a few aluminum machine parts for one of his clients.

It was a test of my maker abilities and I jumped at the chance.

All I would need was a small 3-axis CNC router to cut the parts and it needed to be rigid to cut aluminum.

I started to look for a suitable machine

- I looked at buying a pre-built machine but I didn’t have the cash to buy a good quality one

- None of the machines I could afford were rigid enough to cut aluminum.

- I looked into sending the job to a machine shop, but their quotes were really high and the lead times were stupidly long for my small job

My only and best option was to build my own CNC Router

All I really needed was a rigid table-top machine because the parts weren’t huge so it made good sense for me to build my own CNC router in-house.

Plus, I really needed to have one in my shop.

I searched high and low for a good information on CNC Router Design

I started researching the best ways to design and build a CNC machine. But I found a huge amount of conflicting information and 10,000 different opinions existed. All the so-called EXPERTS were telling me something completely different.

I was expected to blindly accept what they were telling me, and just hope that it all turned out well.

It was a huge leap of faith, which made me really uncomfortable, but I needed to start producing parts quite quickly.

So, I made some wild educated guesses and got to work on my design.

Then my CNC Build Nightmare began

It took me about 4 weeks to complete my drawings and all the detailed parts list.

It had taken me much longer than I had estimated, because I had to design some parts over and over to get them to work.

Then I ordered all the expensive expert-recommended parts that I could afford, and started my build.

It took a lot of fiddling and back and forth to get the frame together so it was close to straight and level.

Too late, I discovered all those expensive components I had bought needed to be mounted really accurately too.

The mounting surfaces needed to be machined completely flat, which I couldn’t do.

I ended up buying a bunch of expensive tools to try get the mounting surfaces flat but never really managed to get them right.

Finally, after a lot of back and forth, I finished the mechanical build.

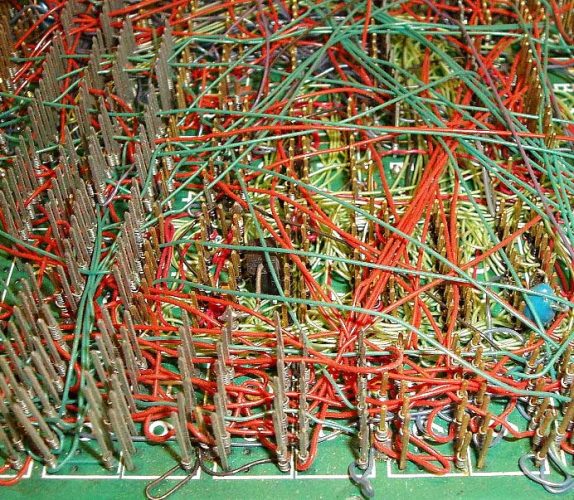

Things seemed to be coming along well and I started to wire the machine up.

Then, I hit the next hurdle…

I struggled to find a reliable wiring diagram anywhere. I looked everywhere but no two diagrams I found matched.

I had to design my own wiring diagrams from scratch.

It turned into a real nightmare to get it working and doubts about my abilities started creeping in.

To this day I’m not sure how I managed to get it to run properly. A lot of guessing and testing.

After a super stressful build, I was finally able set up and cut the first batch of parts.

My family hadn’t seen me for weeks!

Finally I started to cut parts…

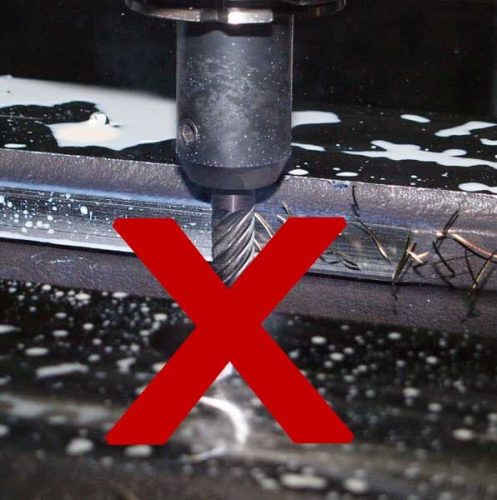

But my expensive CNC machine wasn’t performing as expected!

When I took the first parts off the machine, I realized that things were really BAD! I knew I was in real trouble.

That beautiful machine I had bet my business future on was flexing, chattering and vibrating horribly when it cut the aluminum.

I tried different feeds and speeds but no matter what I did, it wasn’t rigid enough to cut the aluminum properly.

There was no simple fix, because of the complicated way I had designed the machine. I would need start all over again, and now I was out of time and really low on money.

So, with my back to the wall, I sent the job out to a machine shop.

A week later, they shipped the parts directly to Howard’s client. I had a bad feeling about rushing the machine shop.

I had no choice.

Then my worst fears came true!

Howard called me the next day and my heart just sank when I hear his voice. The machine shop really screwed up. All the tolerances were way off and none of the parts fit.

He backed out of our deal and I can’t blame him, I’d dropped the ball badly!

My reputation was in shreds. By blindly following the ‘experts’, I’d destroyed a good friendship and a promising business relationship.

My whole CNC build was a complete waste

– I’d wasted all that money for nothing!

And all I had to show for all my work was a useless and expensive piece of scrap metal in the corner of my shop.

Worst of all is that I’d lost confidence in my abilities.

I crumpled-up my business plan and threw it in the trash and swore I’d never repeat the same stupid mistake again.

Then I locked up my shop and just walked away.

If I was going to live with myself, I only had one way out…

I had to solve the CNC design problem

I knew there just had to be an easy and simple way to approach the CNC problem. I just wasn’t going to let it beat me.

I quickly realized that I needed to trash all the bad ‘expert’ advice and go back to basics.

So I began researching all the machines tools I could find… and study how they were designed and what made them successful.

I looked at a bunch of simple old machine tools and even how WWII fighter planes and weapons were put together. I researched anything I thought would help clear the fog from all those so-called ‘experts’.

I searched for timeless techniques that had worked and produced so many simple and iconic mechanical designs that had served us well for so many years.

I searched for how mechanical designers did it in the times when resources, tooling and labor were really scarce, like during the War.

Those were times when people seem to really excel.

Then I discovered the perfect strategy…

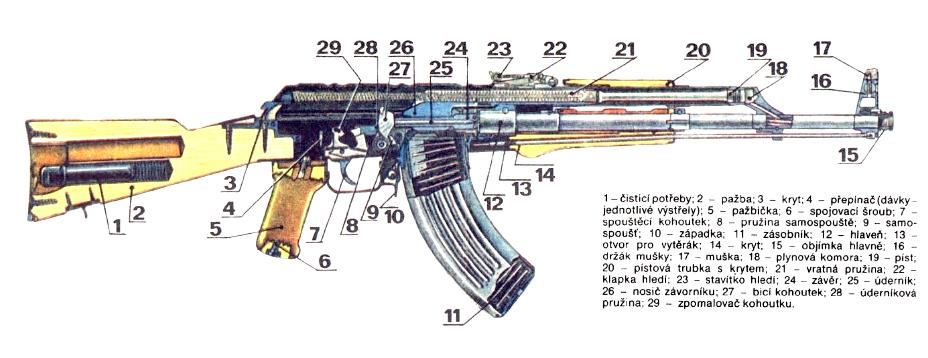

One day I read about Mikhail Kalashnikov, an old Russian weapons designer.

During WWII, he’s the guy who designed the AK47 which is the simplest to build, most manufactured automatic weapon ever produced.

His design was revolutionary, it was super simple to manufacture using the unskilled workers and basic machine tools available to him.

Kalashnikov achieved his iconic design by ignoring all the wisdom of the weapon’s “experts” of the day.

It suddenly all CLICKED, and I knew I’d found a way.

And so I was inspired to developed what I now call my KAL Strategy™

The KAL Strategy™ is a set of simple guiding tips to follow when designing a CNC machine tool.

It’s a system I’ve tested and fine-tuned over time and I’m going to share it with you for free today.

The results have been phenomenal because the KAL Strategy™ simplifies the whole CNC design and build process a lot.

I never really wanted to be a CNC Expert, I was forced into it

I just wanted to build my own working CNC router like many of you people out there.

But I realized, by stupidly throwing away a great business opportunity, that nothing was going to change for me until I worked out a fool-proof, reliable way to prevent it all happening again.

We have a lot in common. As makers and designers, we all face similar day-to-day problems. We just want to get on producing the things we’ve designed.

The only difference is that I’ve managed to work out a simple solution to the CNC problem.

And that’s why you’re here reading this now…

First, you need to understand what the real problem with DIY CNC’s is…

…And it’s much bigger than you may think.

Building a own reliable CNC router shouldn’t be difficult…

When I started, I had no idea that it could be so incredible difficult for me to build a professional CNC machine.

I didn’t understand why there are so many badly performing DIY CNC machines exist out there.

Just look at all the failed machines on YouTube and you’ll know what I mean.

You’re going to be surprised because the problem is NOT what you think it is. And to be clear, it’s NOT because you don’t have the right building skills.

We once knew how to do it simply, why not now?

But, we left the tracks…

Back in the 1950s our factories were changing over from producing weapons for WWII. The War years were exceptional times, people needed to be enterprising just to survive.

There was no time to make things over-complicated, because lives depended on doing things quickly and simply.

But somewhere along the way, we started to believe that we couldn’t get it done by ourselves. We started to believe that anything of quality had to be designed by engineers and made in a factory.

All the information you’ve needed to build a quality CNC on a budget is nowhere to be found!

It’s not your fault, and here’s the reason why…

There are just no in-depth, simple-to-follow, step-by-step guides available that cut through all the BS and the smoke and mirrors.

Everyone’s trying to sell you overkill components you don’t need

The CNC industry intentionally puts out a lot of marketing misinformation.

They’e not going to tell you that you can achieve similar professional results without using the most expensive components.

They don’t tell you that less-expensive parts can perform well if used correctly. The trick is to know how to use them.

So many builders spend a fortune and end up with a massively over-spec’d, complicated machines that are difficult to build without access to expensive machine tools.

No one is showing you the way through.

Everyone’s trying to sell over-priced and weak CNC kits

Most of these kits have frames built from light aluminum sections to save on shipping costs, and they use cheap and junky linear drive components to save money.

They’re toys and not useable as serious machine tools.

The KAL Strategy helps you avoid a CNC build nightmare

Building a pro-quality CNC router is not for everyone.

It’s for dedicated makers who aren’t afraid to put in the hard work to get a reliable professional result

By following the KAL Strategy™ CNC Cheat Sheet you’ll be avoiding the DIY CNC builders’ worst nightmare, which is having to tear it all apart and start over.

If you are confident of your skills and are prepared to put in hard work, then the KAL Strategy™ – CNC Cheat Sheet is a really useful guide to getting on the right track to designing your own DIY CNC Router.

Once you research and draw up your design and then work out each part, you’ll be able to move ahead with confidence.

You can design your own CNC router,

but it takes time and a lot of trial and error

But there’s a MUCH Simpler Way!

You DON’T have to go through those long hours to researching, designing and drawing up to get professional results

Because I’ve put it ALL together for you in one comprehensive package…

You can now skip ALL the trial and error and uncertainty of the CNC design process and start building your CNC right after you read this article.

You can have a professionally designed and tested CNC machine design complete with all plans and drawings and step by step instructions that you need!

There’s now NO need for you to waste your time duplicate all my efforts and reinventing the wheel.

Because I’ve already done all the research, design and drawing for you...

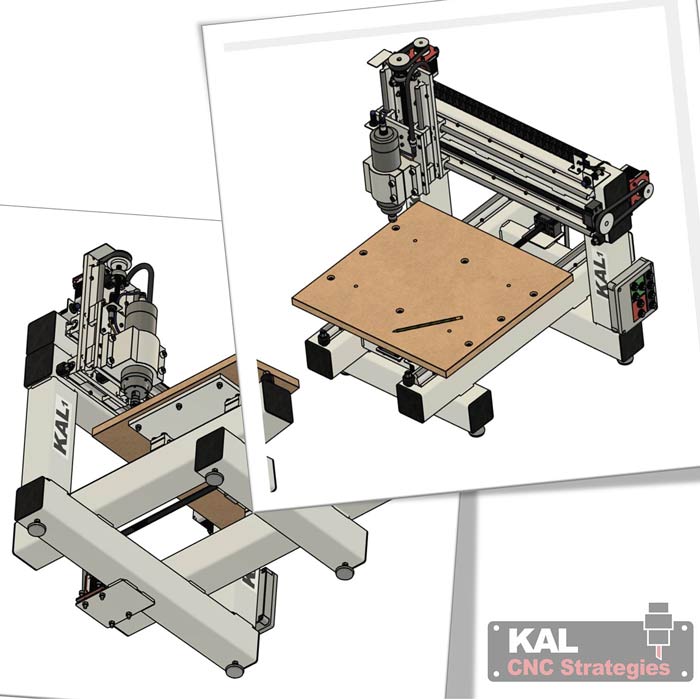

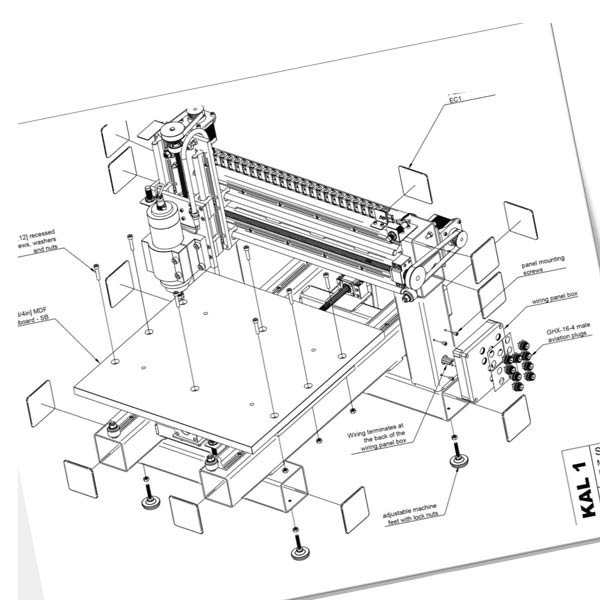

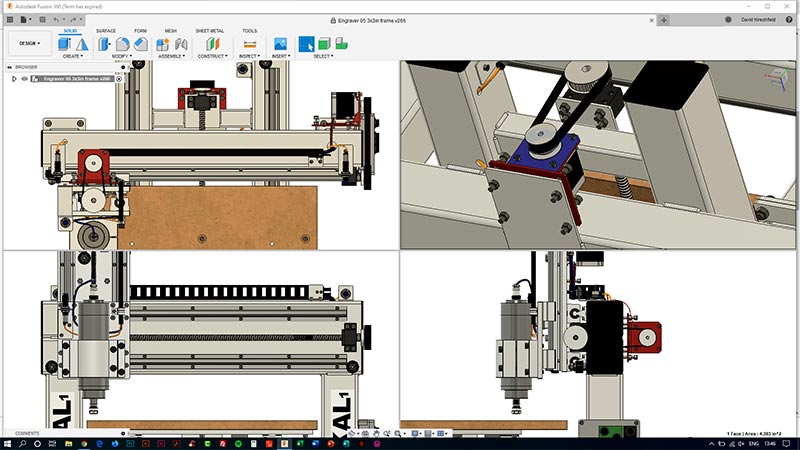

Introducing the KAL1 CNC Package

Everything I’ve learned on my long CNC journey has culminated in this professional CNC router design.

All the methods developed in the KAL Strategy™ have been incorporated into this one of a kind, original CNC machine design.

All the plans and information you willneed to build your own professional level CNC machine are included in the KAL1 CNC package.

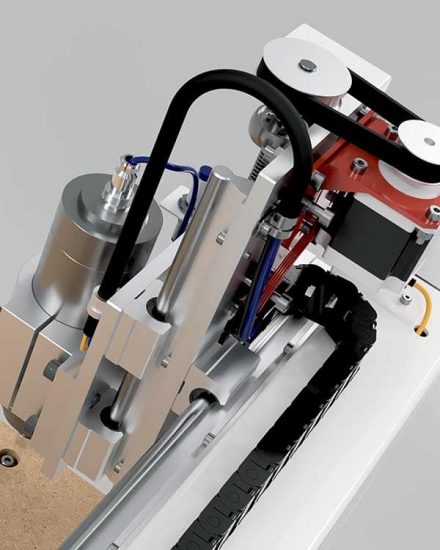

The KAL1 CNC Router is unmatched

The KAL1 CNC Router has been specially designed to be super-rigid.

It can easily cut hard metals like aluminum and brass cleanly, and without fuss!

This is why the KAL1 CNC is so UNIQUE…

It’s designed to be a super-rigid and heavy duty CNC router:

It can easily cut hard metals like aluminum and brass!

It’s designed to be inexpensive to build:

KAL1 leverages all the design principles of the KAL Strategy™ to achieve professional results using inexpensive materials and easily available mechanical components.

It’s designed as a compact table-top CNC that doesn’t waste space:

If you don’t have a whole lot of space in your workshop, then the KAL1 is perfect for you.

It’s a compact, heavy-duty, 3-axis CNC router with a useable cutting envelope of 17.75” x 17.75” x 4” (45 cm x 45 cm x 10 cm)

It comes as a complete package with plans and step-by-step instructions:

The KAL1 CNC Package comes complete with all the information and drawings you’ll need to start building your own CNC router.

It’s designed to be incredibly simple to build:

You can easily build the KAL1 CNC with common tools found in most home workshops.

NO exotic and expensive machine tools like milling machines or lathes are required.

It’s designed to looks super-professional, it doesn’t look home-built

People will have a hard time believing it wasn’t built in a factory. That’s because it is designed by a professional product designer.

The KAL1 requires only basic DIY skills to build

Even if you’ve never built anything like it, the KAL1 CNC Package takes all that into account.

Only basic DIY building skills are required to build it.

The KAL1 CNC Package explains the complete build process in depth with simple-to-understand, step-by-step illustrations.

So, you can easily build your KAL1 CNC at an easy comfortable pace.

The KAL1 is a serious machine for serious builders

It takes dedication to build but KAL1 delivers big results

KAL1 CNC isn’t one of those under-structured, thrown-together CNC kits.

It’s a comprehensive, step-by-step guide to building a heavy-duty CNC router based on the KAL Strategy™.

It’s designed for builders and makers who need a professional quality, super-rigid CNC router with superior performance.

So what exactly is the KAL1 CNC Router?

What sets it apart from other desktop CNC routers?

– The KAL1 CNC is super-simple to build, heavy duty and it’s a real budget option…

– KAL1 CNC is one of the easiest to build, tabletop DIY CNC routers.

– It’s designed to be super-rigid so it can easily cut aluminum and other hard materials.

– It’s also one of the least expensive ways to get a heavy-duty, pro-level CNC router into your shop.

All the best machine tool designs are uncomplicated and have super simple manufacturing processes.

The simpler the machine design – the better the machine.

And that’s exactly what you get with the KAL1 CNC Package

Is the KAL1 right for you?

If you’re looking for an easy bolt-together, hobby CNC router to engrave plywood pictures of your cat, then the KAL1 CNC Package is definitely not for you!

If that’s what you’re looking for, close your browser right now, because then the KAL1 CNC Package is not right for you.

So who is the KAL 1 CNC meant for?

It’s for those of you who are ready to stop looking for that easy miracle-in-a-box, silver-bullet CNC Router solution.

It’s for those who are ready to put in the real work that’s needed to build your own super-rigid, professional CNC router.

It’s for makers who are looking for a serious CNC machine to take their skills up a notch.

There are NO shortcuts to getting professional quality in a CNC router. There are NO easy push-button solutions.

But, if you’re looking for a pro quality CNC to serve you well in your shop, and you’re prepeared to put in the solid work…

…then, KAL1 CNC is as easy as it gets!

So if you’re looking for…

- A complete start-to-finish CNC router build package with plans in feet and inches and metric measurements

- A pro-quality CNC router with a super rigid steel frame that can easily cut aluminum

- A complete set of step-by-step assembly drawings with in-depth instructions

- A CNC router that’s super-simple to build using easily available components…

…then you are in exactly the right place.

Here’s what you’ll get in with KAL1 Package…

- You get the 126-page eBook with 9 in-depth chapters covering the complete KAL1 CNC build from start to finish.

- It’s in easy to read PDF format so you can read it on your computer, tablet or phone or print out the drawings.

- The eBook contains ALL the easy-to-follow drawings, instructions and files you’ll need to quickly and successfully complete your KAL1 CNC build.

Chapter 1 – Design/Build Approach

- Here we go over all the design choices we made when designing the KAL1 CNC.

- We go into detail about the different CNC frames

- We explain the different linear-motion and drive system types and advantages.

- We explain the CNC control box contents and the CNC control software.

Chapter 2 – Machine View Drawings

This chapter has all the assembled machine views so you have a complete detailed reference as you build your KAL1 CNC

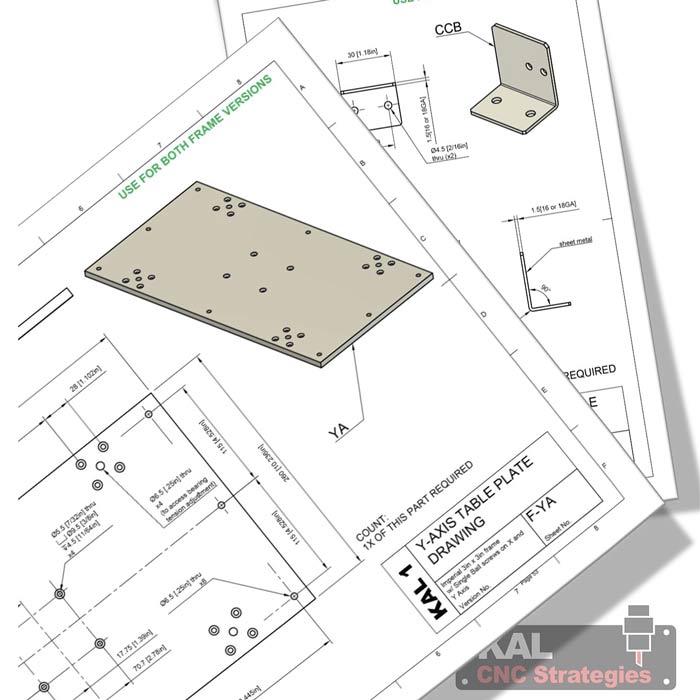

Chapter 3 – Fabrication Drawings

This chapter contains all the detailed drawings needed to fabricate each of the parts of your machine.

Every dimension, hole and weld are clearly called out in inches and mm on each of the drawings with full, easy-to-follow notes.

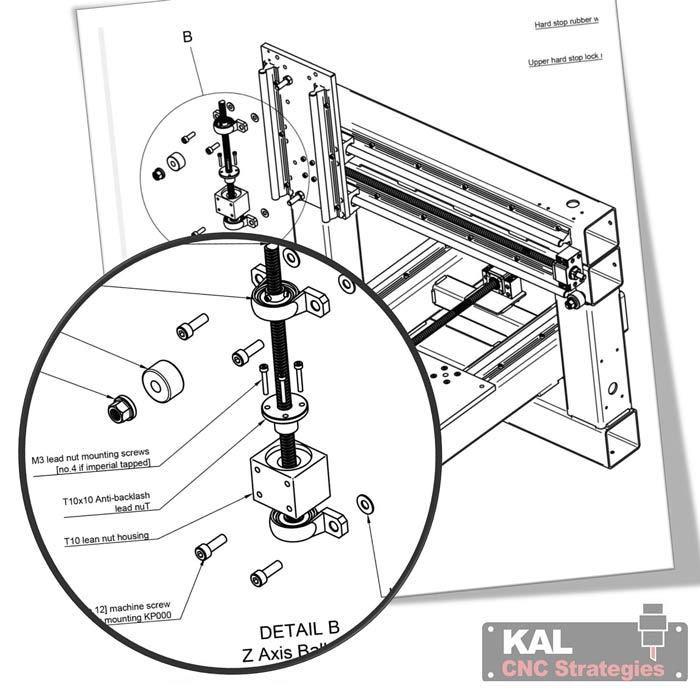

Chapter 4 – Assembly Drawings

This chapter guides you step-by-step through the 28 assembly stages from start to finish.

- You’re shown exactly how to assemble each component in simple-to-follow

3D exploded views. - You’re taken through the assembly process for each of the 28 assembly stages, step-by-step…

- Nothing is missed out and everything, the placement of every screw and nut is illustrated in complete

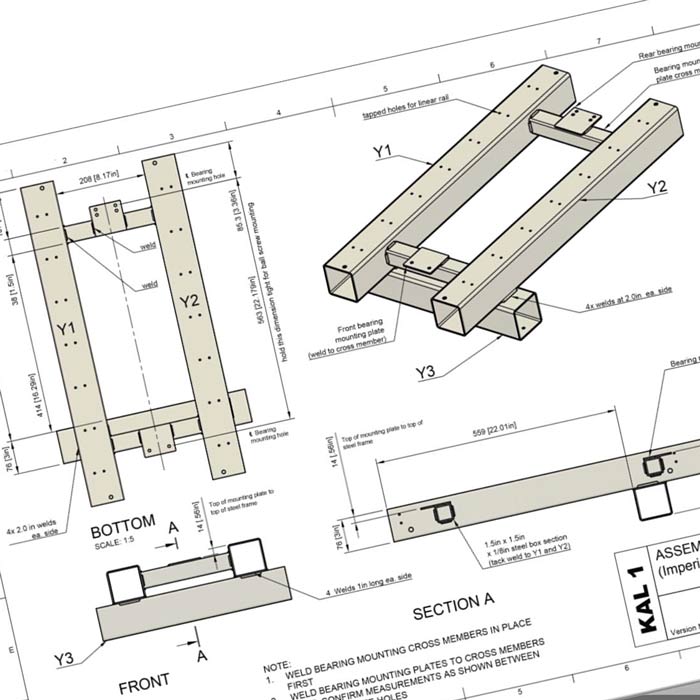

Chapters 5 & 6 – Frame Assembly Drawings

These chapters contain the complete set of drawings you’ll need to assemble your CNC router’s steel frame.

- There’s a chapter containing all the information for each of the 2 different frame options.

Chapters 7 to 9 – Final Stages

These chapters take you through the final stages of your CNC build.

- In these chapters we cover the CNC Control Box layout and how to route all the control and signal wiring in detail.

- You also get the Structural Analysis Studies showing how well the steel frame performs under cutting loads.

Plus, with your package you’ll get…

The electronic DXF CAD files of all the CNC mounting plates so you can print them as templates or even cut them on a friend’s CNC router.

A digital file of the official KAL1 logo to give your CNC machine that professional touch.

So, you can see, with your package you’ll have everything you need to start building your own professional quality KAL1 CNC router just minutes after you download the package

And the best part of the KAL1 Package is…

- How quick it is to get started

- That the KAL1 CNC is really simple to build

- How having the package cuts out long months of researching and second guessing

- How beautiful and professional the completed KAL1 CNC looks.

Right now, you’re probably curious how much the KAL1 CNC Package is.

You may be thinking that this complete package would cost you over $500.

The good news is, that’s not the case.

When you buy the KAL1 Package today:

You’ll be avoiding those weeks and months of wasted time researching, drawing up and testing your own designs.

You’ll be able to start your CNC build without delays. There are NO unknowns and the path ahead for your CNC build is clearly mapped with NO surprises

All the engineering heavy lifting has already been done for you so you can really enjoy the stress-free building process

So, if you need a super-rigid CNC Router, that performs professionally and easily cuts through aluminum, and you need to build it on a limited budget.

And you need complete step-by-step drawings and instructions in one professionally designed package…

…then the KAL1 Package is right for you

When I first started putting together the package, I decided that a fair retail price would be $297.

But, I’ve changed my mind and I’ll tell you about that in a moment….

To complete your CNC build, you’re going to need to have…

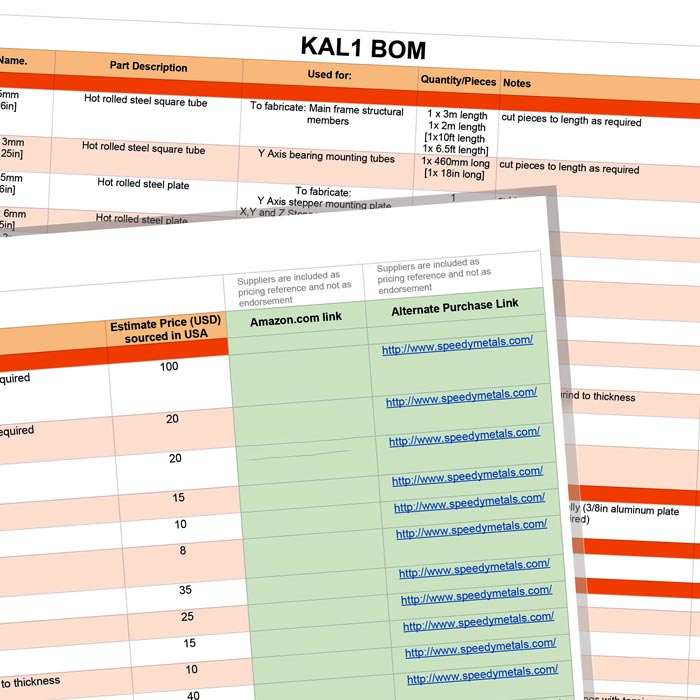

An accurate Bill of Materials (or BOM)

There’s really no way around it,

because you’ll be completely lost without it.

Now, you won’t have to do all that work because I’ll be giving you the complete detailed KAL1 BOM as a free bonus!

The KAL1 BOM lists ALL the materials, parts and components with quantities, purchase links and pricing.

You’ll easily be able to order products online by simply clicking on hyper-links next to the products

The BOM by itself is worth $50

Having this pre-made BOM will save you huge amounts of time…

Adding the BOM in, brings the total value of the KAL1 package to $347

Of course, you could just follow the information in the KAL Strategy™ CNC Cheat Sheet to guide your CNC design.

And if you carefully follow all the tips I gave you, it’s possible you may be able to come up with your own working design.

But remember, it could take many long nights and weeks to finish the drawings.

You’ll still need to test each of the designs and make sure they work.

If you choose to go it alone, it could end up costing you 5x or 10x more than the investment you’ll make today.

And that’s NOT what I want for you, because I’ve already been there.

I want get my design out there into the maker community because it’ll end up helping a lot of makers who are just starting out. They need to move up to the next level just like I did.

The only way I’m going to be able to help is to make the KAL1 CNC Package more affordable.

And that’s why I’m discounting the price…

In just a couple of minutes you can have the full

KAL1 CNC Package + Bonuses.

Click the buy button below.

Here’s my NO RISK promise to you…

I’m so confident that the KAL1 CNC Package is going to work for you, that I’m going to give you a triple, money back guarantee.

- If you don’t feel that the KAL1 CNC Package delivers for you in 60 days, I’ll give you your all money back!

- For whatever reason, if there’s anything you don’t like about KAL1 CNC Package, I’ll give you your all your money back, NO questions asked!

- Even if your neighbor’s dog barks too loud, or your morning coffee gets cold, any reason whatsoever, I’ll give you 100% of your money back

If all of that hasn’t got you so excited that you click the Buy Button.

I was going to tell you about this bonus on the sales landing page but guess what?

I’m going to tell you what it is right now.

The KAL1 CNC Wiring Diagram

The wiring diagram eliminates all your wiring guesswork and testing headaches.

…and I’m going to include it free with your purchase today…

You won’t find this wiring diagram anywhere, on the internet or in any library.

The KAL1CNC Wiring Diagram took weeks of design and testing to perfect.

I could easily sell it for $50 as a standalone product but, you’re getting it included today as a free bonus.

It’s included free with your KAL1 package!

You get the full electrical wiring diagram showing you exactly how to wire up the KAL1 CNC.

It fully details exactly how to wire the whole machine, including all the limit switches, stepper motors, spindle control and the complete CNC control box.

So, join other successful Makers now!

You’ll be joining the thousands of makers and builders using CNC routers in their shops every day to produce incredible and unique products. They’re making drones, electric guitars, auto and bike parts, signage and thousands of other incredible things.

Their inventions are becoming reality.

Here are just a few of the many amazing things you could make with your KAL1 CNC.

The sky’s the limit!

So click on the Buy Button below and moments from now, you’ll be taken to the Buy Page to get your package.

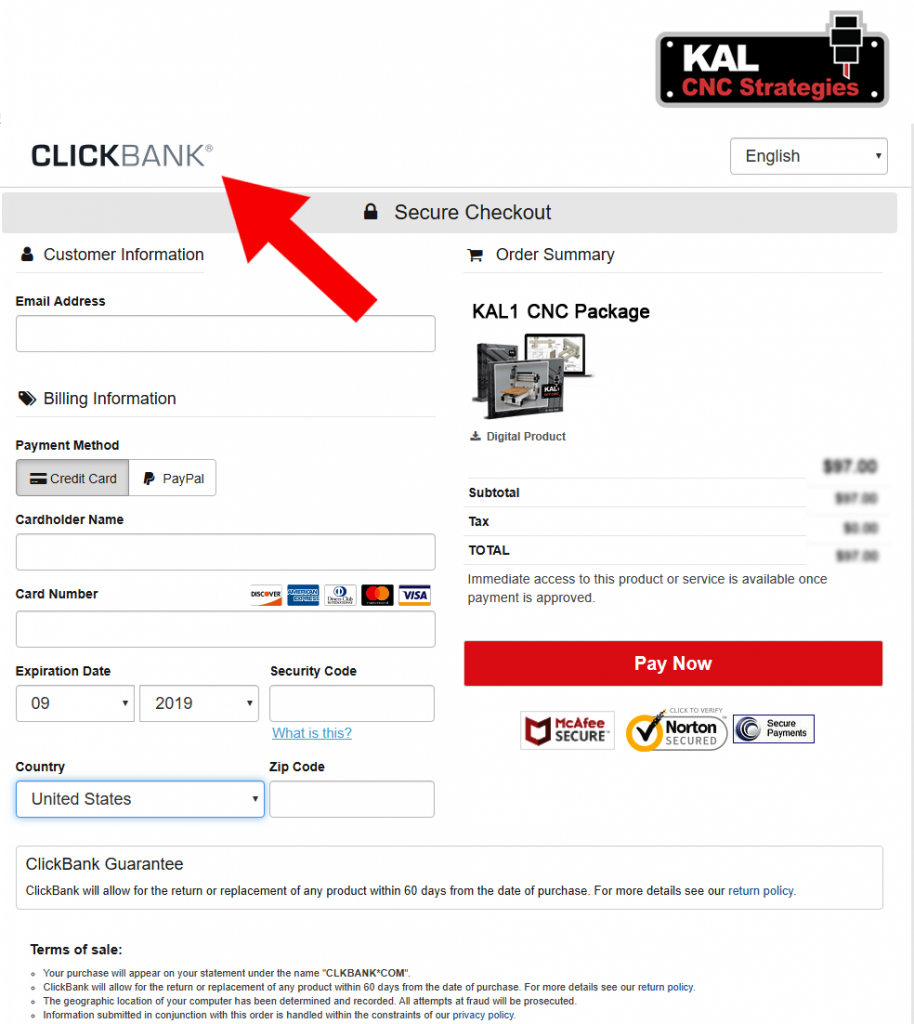

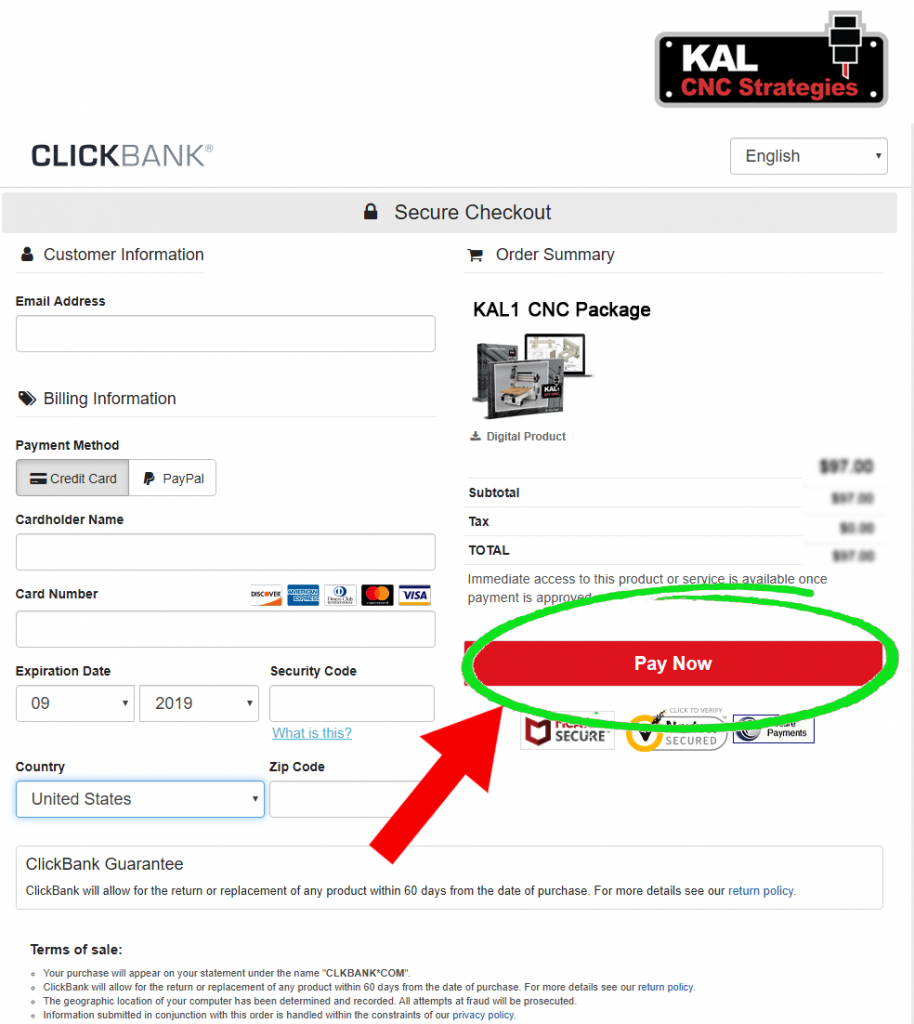

Here’s how you’ll check out…

When you click on the Buy Button here’s what you’re going to see. You’re going to be taken to our secure Clickbank checkout page. It’s going to look something like this:

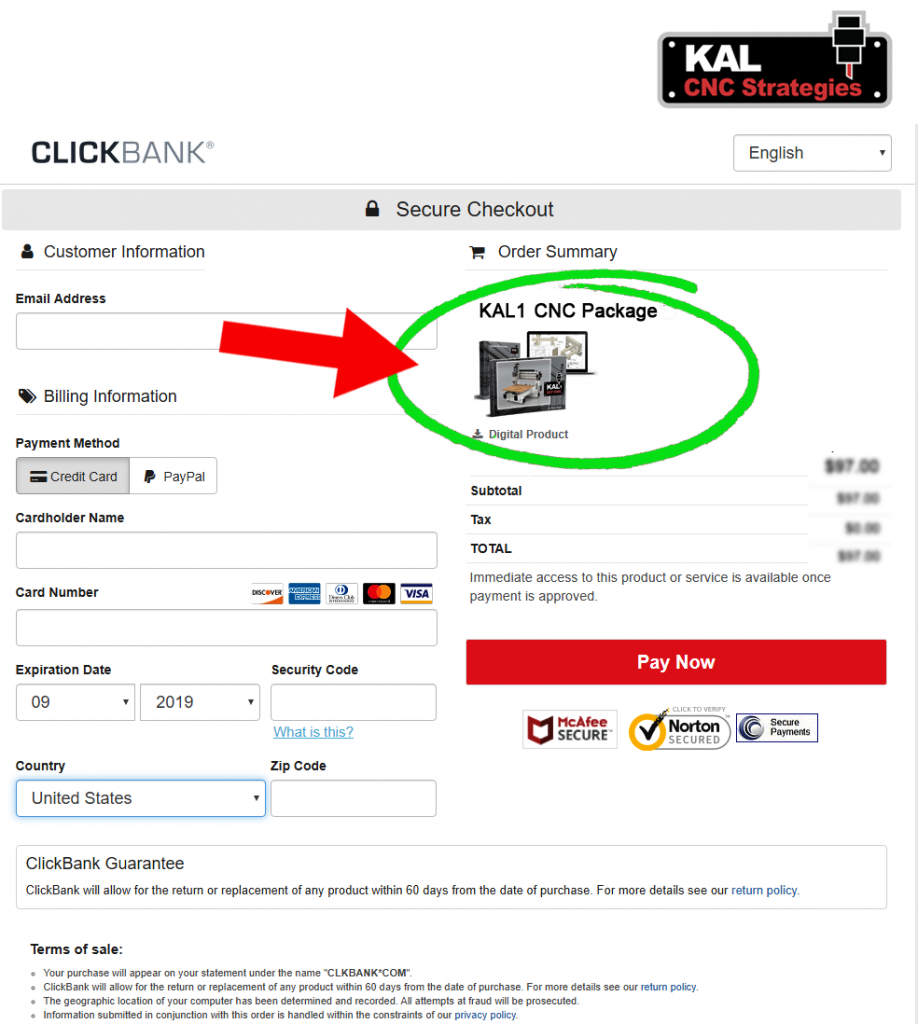

You’ll know you’re in the right place when you see the KAL1 CNC Package image:

Notice, our checkout handled via Clickbank and is 100% Secure:

Also, you’ll see your no-risk 60-Day Money Back Guarantee on the Clickbank order screen:

And when you click the Pay Now button:

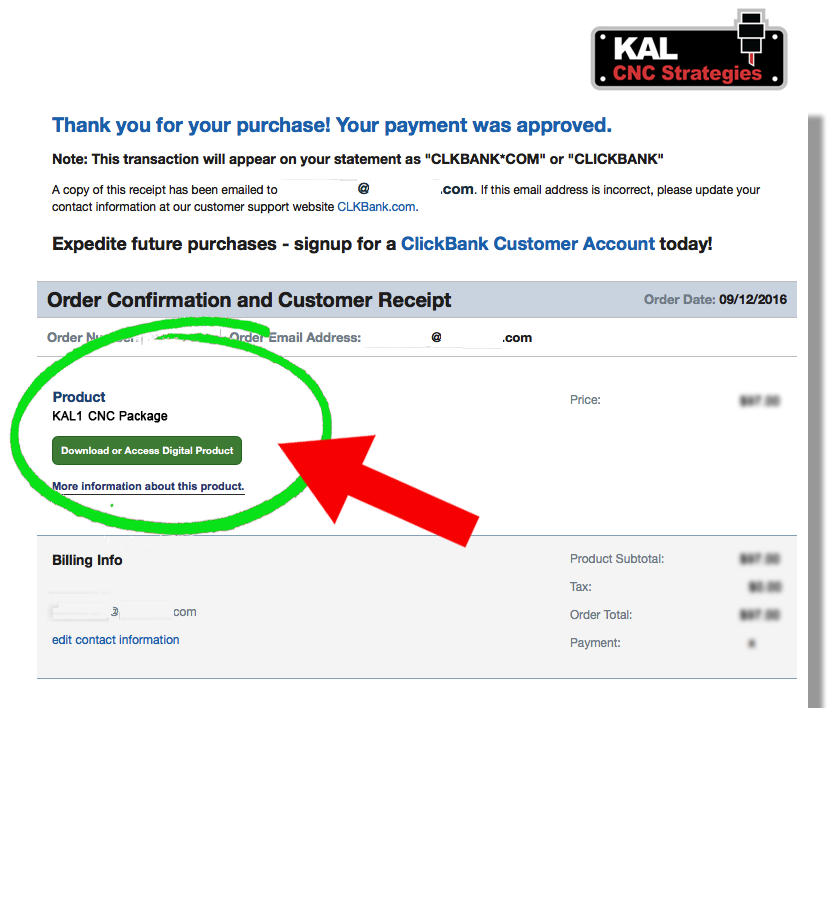

You’ll then be taken to the Order Confirmation screen.

Simply click on the link and your download will start.

In just a couple of minutes you’ll have the full KAL1 CNC Package on your computer.

The KAL1 CNC Package is in .PDF format and can be read with Adobe Acrobat Reader which is a free download, and other similar programs.

To download your digital files, you will find a link to the KAL1 Download page on the Table of Contents of your eBook.

Without a detailed set of plans and full assembly instructions your CNC Router build can take many, many extra weeks or months to design, draw up and test.

- And that’s NOT including the time to choose and search for all the hundreds of parts and components.

- And then you’ll still have to research, test and design a complete working wiring diagram.

- You could spend hours just staring at a blank piece of paper wondering where you should start.

This is what you’ll be receiving today…

With your purchase you’ll get…

- The complete KAL1 CNC Package which includes all the 9 chapters we covered earlier.

- You’ll also get the detailed KAL1 BOM listing all the materials part, fasteners and electronic parts, everything you’ll need.

- Plus, you’ll get the original .XLS spreadsheet file of the KAL1 BOM so if you ever need to revise it, you can.

- You also get the set of fabrication drawings covering each part you will build for your KAL1 CNC

- Plus, you get the step-by-step assembly drawings with the easy-to-follow 3d exploded views with written instructions.

- Inside we explain how to correctly align the X, Y and Z axes to assure your CNC performs accurately

- Plus, you get the detailed design and layout for all the components inside CNC control box.

We show you how to lay out the control boards and power supplies and how to route the wiring so you avoid electrical interference

- Plus, included as a bonus is the complete KAL1 CNC Wiring Diagram so there’s no wiring guesswork.

It shows you how to correctly wire and ground every electric and electronic component to avoid any disruptive ground loop problems

- Plus, you get DXF CAD files for all the mounting plates, so you can print out full-scale drilling templates or even cut and drill those parts on a CNC router if you choose to

The moment you download your KAL1 CNC Package today, all of this will be yours.

It’s taken us a lot of time, effort and expertise to put this package together.

It easily has a retail value of $347

So, take advantage of this great offer today and get the complete KAL1 CNC Package + Bonuses for an incredibly low price

At this point you have choices to make:

-

- First, you can keep on going it on your own and maybe take 6 months or a year to finish your CNC router build. In fact, you may NEVER get around to building a reliable, working CNC machine.

- The second thing you can do is to follow the strategies I gave you in the KAL Strategy CNC Cheat Sheet above. You can use that information to design and eventually build your own CNC router.

Do you really want to go it alone?

- You’ll still need to design and draw up every part for your CNC router and make sure they all to work together perfectly in the end.

- You’ll still have to work out the best way to assemble your CNC machine, to align the components and be sure it will be rigid enough

- And then you’ll still need to spend time choosing and finding parts and creating your own detailed BOM

- And you’ll need to work out a working CNC control box layout and choose the power supplies and the electronic control components

- Then you’ll need to design a working wiring diagram for the control box and how to connect it to the CNC router

- And you still won’t be assured that your steel frame is rigid enough unless you simulate the engineering in a computer engineering program

So make the smart decision

Choose to take advantage of this great offer today!

If haven’t taken action yet and you’re still reading this, there can only be ONE reason

It’s can’t be price – you know you can afford this and it can’t be the quality of the package…

We’ve shown you that it contains everything you’ll need to easily build your KAL1 CNC

It must be that you still have questions that I’ve missed.

I’ll go through a few in the FAQ below.

You have a full 100% Money Back, 60-Day Guarantee for any reason, no questions asked. There is absolutely NO risk to you.

The KAL1 CNC Package takes into account ALL skill levels and has especially been designed to be forgiving and easy to build. You will just need basic tools and DIY skills.

It all depends on the time you have to put in to it. If you go at it full time and have all the parts and materials pre-ordered, it could be as short as a few days.

The tools required are really basic and there’s a complete

list in Chapter 1 of the package.

Any number of things. You can make signage, drone parts, electric guitar bodies, car parts, prototypes, you can even engrave and cut stone with the right cutting bits. The possibilities are endless.

The CNC control software is run on a PC computer and only needs a really basic system. In addition, you will need a CAD CAM program to create

your cutting tool paths. I like Autodesk Fusion 360 for which is currently offered free to startups and hobbyists.

The KAL1 BOM included in the package has links to Amazon, eBay and other online suppliers. You can get up to date pricing for parts by clicking the links.

I recommend Linux CNC as I mentioned earlier. It’s downloadable free as a package with the Linux OS and that’s all you’ll need to run the CNC machine.

The KAL1 DIY CNC is specially designed to cut hard materials but it can easily cut wood and plastic. There are bits or end mills designed for the different material types.

Yes, I’ve surveyed what’s available on the market at the time of publication. Kit CNC’s of similar size and capacity sell for 3 or 4 times what the KAL1DIY CNC costs to build and factory-built machines will cost you upwards of 3 to 4 times.

The KAL1 CNC is your best budget CNC router option if you’re looking to build a reliable and serious machine.

There are no comparable CNC packages that I know of on the market.

Everything points to the KAL1 CNC Package being the best available option

So click on the Buy Button below and get started on your own incredible CNC journey in just minutes!

Thanks for taking the time to read about the KAL1

Wishing you the best on your CNC journeys,

Dave Field – KAL CNC Strategies

Professional Product Designer

ClickBank is the retailer of products on this site. CLICKBANK® is a registered trademark of Click Sales Inc., a Delaware corporation located at 1444 S. Entertainment Ave., Suite 410 Boise, ID 83709, USA and used by permission. ClickBank’s role as retailer does not constitute an endorsement, approval or review of these products or any claim, statement or opinion used in promotion of these products.

©2019 KAL CNC Stategies 2019 – Dave Field

Leave a Reply